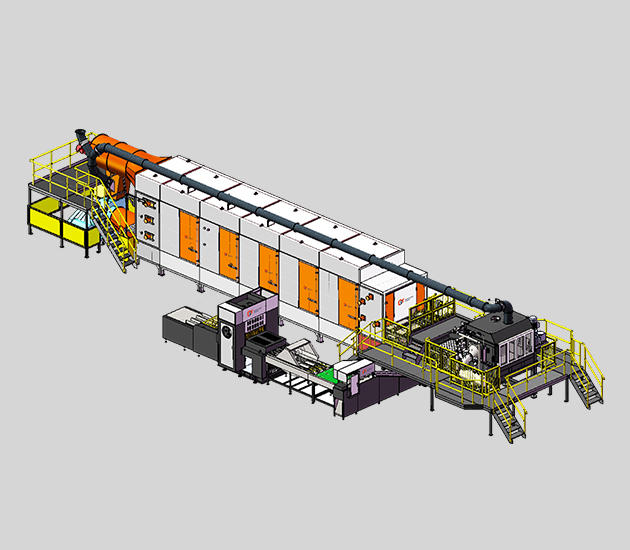

The automatic rotary egg carton production line is composed of a pulping system, forming system, drying system, stacking system, vacuum system, high pressure water system and an air compressor system.

The automatic rotary egg carton production line is composed of a pulping system, forming system, drying system, stacking system, vacuum system, high pressure water system and an air compressor system. It is specially used to produce egg cartons. (10cells,12cells,15cells,18cells egg cartons). Using waste paper such as waste newspaper, waste carton paper, office paper, scrap and other materials as raw materials, a slurry is prepared with a certain concentration through hydraulic crushing, filtration, water injection and other processes, and is vacuumed on a special metal mold by a forming machine. It is absorbed into a wet billet, dried by a drying line, hot pressed on the line and then stacked.

The host system consists of a rotary forming machine, a six-layer drying line, a conveyor line, a fully automatic hot press machine and a stacker. The biggest feature of the production line is that it can complete online automatic hot pressing, with a high degree of automation, which greatly saves labor costs.

Models:EC3600 / EC5400 / EC9600

Production line composition: Forming System: 2drop/4drops/8drops rotary (with the function of washing mold / product burrs, equipped with preheating system).

Drying System: 6 layer drying line/8 layer drying line.

Hot Press System: 2 trays, 3tray or 4trays each time.

Stacking System: two channel stacker ; three channel stacker ; four channel stacker(with automatic counting function)

Forming platen size(mm): 1900x400 / 2250x400

Design capacity of production line(based on 30cell egg tray): 3600pcs/hour / 5400pcs/hour / 9600pcs/hour

Forming Type: Rotary Suction molding

Forming cycle time: ≤20 plates/minute

Mold Distribution: 6pc/drop; 8pc/drop(basing on 10/12 cells egg tray)

Product height: ≤70mm

Heating fuels: Gas, Thermal oil, LPG, LNP or steam(if with steam, the drying system is to be lengthened basing on the specific output capacity)

Control method: PLC + touch screen

Remarks: The above parameters are for reference. Due to the continuous development of technology, relevant data will be continuously updated

| Models | Output Capacity | Floor | Staff | Electricity | Water |

| EC2700 | 2700pcs/hour | 45×24Height≥4M | 4persons/shift | 150-180KW/Hour | 0.4-0.6Tons/Hour |

| EC5400 | 5400pcs/hour | 60*24Height≥4M | 4persons/shift | 240-280KW/Hour | 1.6-1.8Tons/Hour |

| EC9600 | 9600pcs/hour | 70*24Height≥4M | 6persons/shift | 360-420KW/Hour | 2-3Tons/Hour |

ABOUT BESURE

In 1997, BST team imported the European production line to China and started the business of molded pulp products production. During the past 24 years, BST team dedicate themselves to the development of pulp molding industry and continue to extend to the downstream industry. BST has now become the group corporation of R & D, manufacture and sales of the whole pulp molding production line, mold and moleded pulp products. It' s also a China-Europe cooperative international company with foreign factories around the world and the first listed pulp molding equipment manufacturer in China.

A China-Europe cooperative company and international group.

A China-Europe cooperative company and international group.

The 1st listed company of Chinese pulp molding machine manufacturers and high-echnology company.

The 1st listed company of Chinese pulp molding machine manufacturers and high-echnology company.

Focusing on pulp molding equipment for over 24 years, the leader for world high-end pulp molding equipment.

Focusing on pulp molding equipment for over 24 years, the leader for world high-end pulp molding equipment.

Serving more than 400 customers all over the world with 6 local service centers.

Serving more than 400 customers all over the world with 6 local service centers.

FOUCUS ON PULP MOLDING EQUIPMENT

BeSure headquarter is located in Foshan GuangDong which is the equipment manufacturing center in China, focusing on R&D, manufacturing and sales of various kinds of pulp molding equipment and molds. The factory covers an area of 38000 square meters and has more than 250 employees.

BeSure technical staff accounts for more than 50% of the total number of company. The current staff number for equipment R & D , engineering installation and commissioning, electrical engineering process , technical support, mold design and making, production , quality control , sales is 131 in total, including 8 doctors, 19 masters, covering multiple disciplines such as mechanical, electronic, thermal engineering, fluid mechanics, paper making, product design, engineering design etc...

The equipment workshop is divided into several parts,including cutting, welding, assembling, painting, processing, electrical assembling and so on . There are different kinds of processing equipment such as CNC machine, milling machine, drilling machine, lathe, shearing machine, bending machine, wire cutting machine, etc.

Mold manufacturing workshop includes CNC processing, drilling, mesh covering, polishing, assembly and other processes. The workshop is equipped with tableware and fine packages machine for products R & D, testing and improving. At the same time it's also used for customers visit and technician training.

There is a sample workshop for mold tesing, sampling and small quantity products production. There is an entire equipment testing system including pulping system, vacuum system, high pressure water system, compressed air system for ex factory equipment commissioning to ensure that all the equipment is qualified before shipping. In order to improve the equipment intelligence, BST set up an R&D center in Europe where the world pulp molding industry originated. There are 6 employees currently and the center is focusing on the development of automatic equipment and production line, helping on BeSure technology innovation. At present, BST has several technologies which are the first innovation in China and has several national patents, leading the world pulp molding industry development. In July 2016, BeSure and Siemens achieved the strong alliances to facilitate pulp molding production line towards intelligence.

Feel free to contact us

The first thing we do is meeting with our clients and talk through their goals on a future project.

During this meeting, feel free to communicate your ideas and ask lots of questions.

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

Copyright © 2025 BeSure Technology Co., Ltd. - www.mybesure.com All Rights Reserved.粤ICP备2025367321号