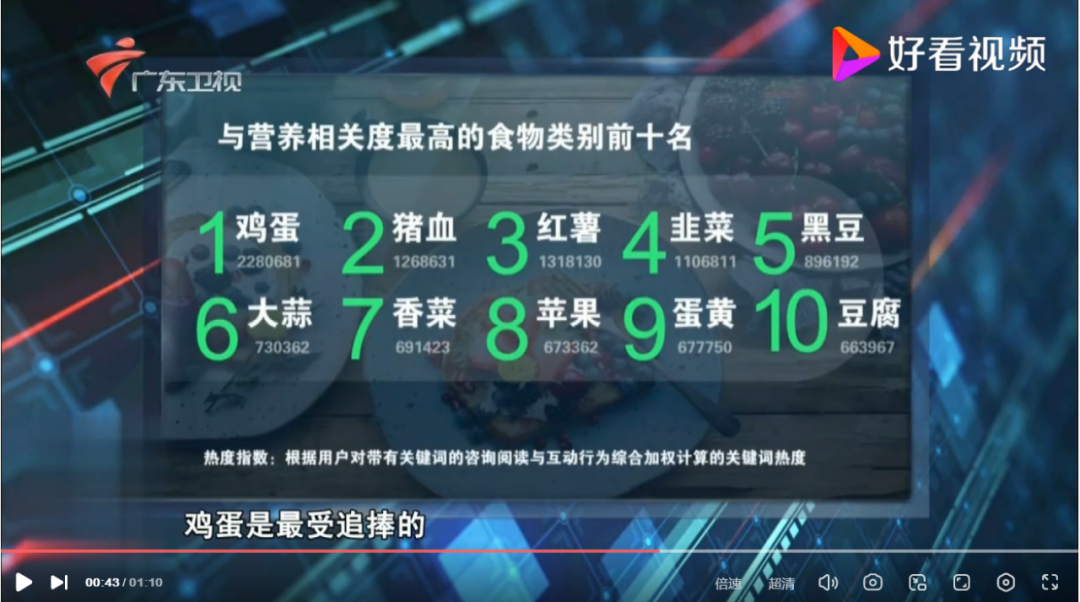

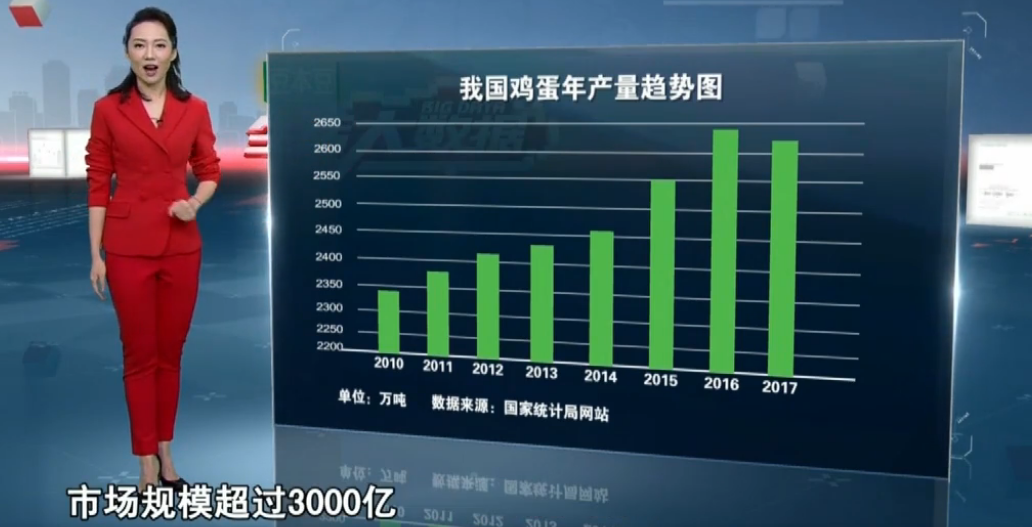

As the world's largest egg producer and consumer, China has an annual output of more than 31 million tons and a market size of 300 billion yuan.According to the "Big Data on Food Nutrition and Health Concerns of Chinese Residents", eggs are the most sought after food among the foods with the highest nutritional relevance searched by Internet users. Egg demand grows steadily.

It is reported that "Guizhou Fengji Ecological Agriculture Technology Co., Ltd.", a leading domestic mid-to-high-end egg brand, has completed the C round of financing of RMB 600 million, setting the largest financing scale for egg brands in the field of basic ingredients.It can be seen that the egg market has expanded rapidly in recent years, and the egg packaging market is worth looking forward to!

Growing demand for eggs is expected to drive the growth of the egg packaging market.According to Coherent Market Insights, the global egg packaging market was valued at USD 4,923.8 million in 2020 and is expected to exceed USD 7.6 billion by 2028.Egg packaging market has a broad market prospect.

Key Trends in Egg Packaging

Environmental protection has become a trend in the context of global plastic ban.Pulp molding has become the main force to replace plastic and has entered a period of rapid development in recent years.Pulp-molded paper egg trays and paper egg boxes are ideal products for egg packaging due to their good protective properties, recyclability and compostability, and low prices.

Automatic Intelligent Packaging Equipment

Since the added value of egg trays and egg boxes is not high, it is necessary to improve product quality and reduce production costs.Advanced automation and intelligent production equipment, as well as stable and efficient operation service guarantee, have always been the strong demands of the egg packaging industry.

BESURE Technology has been focusing on the R&D and manufacturing of high-end pulp molding production lines for 24 years. It has continued to develop and innovate, solve problems for the industry, and help the pulp molding industry to develop in the direction of automation, intelligence and energy saving.

The fully automatic high-speed egg box production line independently developed by BESURE Technology is a pulp molding equipment specializing in the production of 6, 8, 10, 12, 15, 18 egg boxes. The production line integrates pulping, forming, drying, hot pressing and stacking, and has the advantages of high degree of automation, simple operation and intelligent control.

The advantages of BESURE automatic high-speed egg carton production line

1. High-speed hot press machine

The equipment is driven by servo motor + full mechanical structure, and the cycle time is only 1.8S. BESURE is one of the three companies in the world with this mature technology.

2. High speed egg carton labeling machine and printing machine

·High-speed and high-yield: the single machine capacity is 50 pieces/min.

·Driven by servo motor, can be used for different egg boxes.

The high-speed hot-pressing machine, egg carton labeling machine and printing machine of BESURE solve the problem of the integration of back-end matching of egg carton production line, and gradually align with the world's top technology!

BESURE automatic egg tray production line can be used to produce egg trays, fruit trays and other tray products.The production line is high-efficiency, high-yield, energy-saving and high-speed. It is the leading egg tray production line in China.

Advantages of BESURE automatic egg tray production line

1. Automatic pulping system

·The pulp system can automatically adjust the pulp concentration, the adjustment accuracy can reach: 0.01%, and the pulp concentration is stable.

·Multiple devices are adopted to remove the impurities in the raw materials, and the slurry has a high cleanliness.

·Using a deflaker to refine the pulp and scraps to make the fiber evenly distributed, so that the product quality is good.

2.Energy-saving drum machine

·Less molding surface to save mold cost.

· The device runs blocks up to 20 boards per minute.

·Dynamic and static ring design, the moisture content of molded products is as low as 69%.

3.Multi-layer drying line

·It reduces the consumption by 24% compared with the traditional single layer drying line.

·The thermal efficiency of the drying line is as high as 90%, and the exhaust gas can be recycled.

·Multi-layer occupies less space and saves space.

·Energy can choose natural gas/diesel/steam.

The automatic egg tray production line with fast operation, high production capacity, small footprint, high efficiency and energy saving, full line matching, and incremental cost reduction is not only a breakthrough for BESURE, but also a great progress in the pulp molding industry.

At present, the full-automatic production line of BESURE Technology covers the application fields of tableware, cup lids, ordinary industrial packaging, fine-art industrial packaging, egg trays and egg boxes, medical supplies and other fields. BESURE continues to meet the development needs of current packaging users and packaging enterprises with intelligent technology of scientific and technological innovation.

Catching up with the era of banning plastics, BESURE Technology will help packaging companies to go further, faster and more smoothly on the packaging road.

Copyright © 2025 BeSure Technology Co., Ltd. - www.mybesure.com All Rights Reserved.粤ICP备2025367321号